Highlights:

- Mining operations to restart at the San Agustin Mine in H2, 2025, with initial production expected in Q4

- Operations analysis supports a post-tax NPV5% of US$35.25M, IRR of 548%, CAPEX of US$4.2M and an output of 45,000 total gold ounces produced at a US$3,000/oz gold price

- Restart provides confidence for the first significant Heliostar investment into the future of San Agustin, aimed at extending mine life

- Drilling will commence immediately in H2, 2025, on oxide expansion targets, followed by sulphide porphyry/breccia exploration

Heliostar Metals Ltd. (TSX.V: HSTR, OTCQX: HSTXF, FRA: RGG1) (Heliostar or the Company) is pleased to announce the restart of mining operations at San Agustin, located in the state of Durango. Heliostar presently produces gold from residual leaching at the San Agustin Mine. The Company will increase production by mining the mineral reserve, principally in an area the Company describes as the Corner Area. This is a key milestone to unlock increased value from San Agustin.

Heliostar is pleased to have met its forecast timelines to recommence mining at San Agustin. commented Heliostar CEO, Charles Funk. Mining the Corner Area will produce 45,000 ounces of gold from the current reserve. It will generate US$40M in cash flow at a US$3,000 gold price. Heliostar has made this restart commitment, having complied with all the requirements to start mining and having approximately US$30M in cash on our balance sheet to fund the necessary capital.

As the largest local employer, this milestone provides job stability and provides for expanded economic opportunities for our nearby communities and throughout the state of Durango. For Heliostar, it marks a shift from residual leaching to active mining, increasing production and improving cash flow through 2026. It also provides the confidence to begin new investment in growth at San Agustin. This will include drilling aimed at converting oxide resources to reserves and testing sulphide targets that share characteristics with deposits such as Pe�asquito and Camino Rojo.

Technical Report Summary

On January 14, 2025, the Company filed an amended and restated technical report titled San Agustin Operations, Durango State, Mexico, NI 43-101 Technical Report prepared by Mr. Todd Wakefield, RM SME, Mine Technical Services, Mr. David Thomas, P.Geo., Mine Technical Services, Mr. Jeffrey Choquette, P.E., Hard Rock Consulting, Mr. Carl Defilippi, RM SME, Kappes Cassiday and Associates and Ms. Dawn Garcia, CPG, Stantec with an effective date of November 30, 2024 (the Technical Report).

The life-of-mine (LOM) plan set out in the Technical Report indicates that a probable mineral reserve of 68,000 ounces of gold can be exploited over a 1.2 year mine life at an all-in sustaining cost (AISC) of US$1,990/oz Au. The initial capital cost in the Technical Report is estimated at US$4.2M.

The Technical Report demonstrates a post-tax NPV5% of US$35.3M, an IRR of 548% and a payback period of 0.2 years for the upside case at a $3,000/oz gold price.

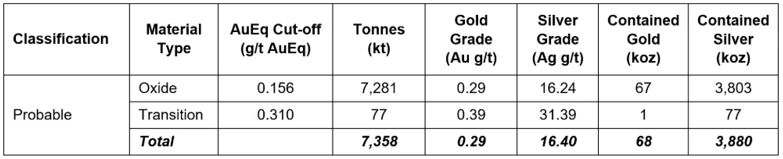

The mineral reserve estimate included in the Technical Report is based on the operation of the existing crusher and conveyor system having a nameplate throughput capacity of about 30,000 tonnes/day and continued operation of the heap leach and carbon-in-column (CIC) process circuit to processing ore from the expanded open pit. The mineral reserve estimate included in the Technical Report is presented below. The expected operating performance and cost forecasts were compiled with the benefit of benchmarking historical performance at San Agustin. This was supplemented with the input of seasoned professionals knowledgeable of the conventional technologies being used at San Agustin, the expected consumption quantities of key supplies, and commercial pricing for goods and services in Mexico.

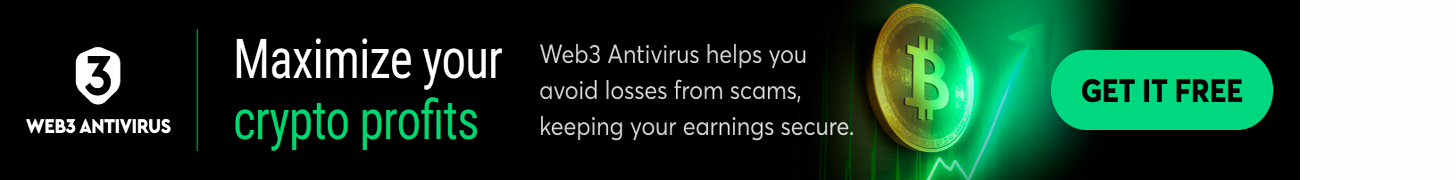

Figure 1: View of Corner Area looking to southeast showing the current reserve model and planned pitshell.

Restart Steps

In 2022, the previous operator of the San Agustin mine reached a private surface rights agreement to access a portion of the deposit referred to as the Corner Area. Despite this, mining operations ceased at the mine in late 2023 due to a lack of permit accessible mineral reserves.

In July 2025, Heliostar complied with all required applications and received the required approval to undertake this open pit expansion. The relevant application was submitted in Q4, 2024. Further, the Company has also received a variance to its environmental impact assessment (MIA) to increase the height of the San Agustin leachpad from 77 to 88 metres in height. This variation will save approximately US$5M in capital during the mining of the Corner Area due to not having to prepare an extension to the existing leachpad.

Heliostars restart plan will include selecting civil, drilling and mining contractors, moving of a power transmission line, establishing additional access roads on site and removing and stockpiling the vegetation and topsoil present over the Corner Area. This work is anticipated to be undertaken in Q3 and Q4, allowing for the first stacking of new ore and subsequent new gold production from the Corner Area in Q4, 2025.

Oxide Growth Targets

The restart of mining at the Corner Area expands the mine life at San Agustin. With the longer production timeline and confidence in the ability to convert resources to gold production, Heliostar will commence a drilling program seeking further mine life extensions.

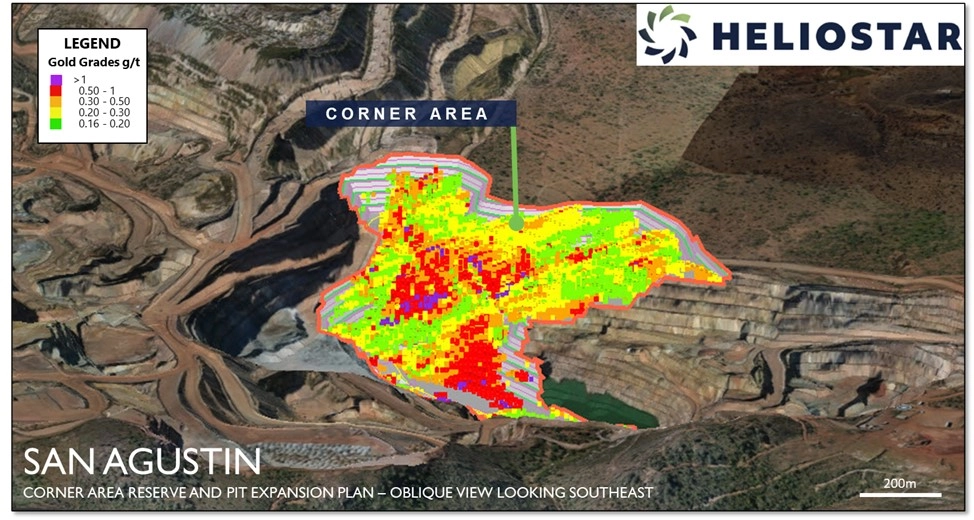

The immediate focus for growth is on near-surface oxide material that could be processed through the existing facilities. The Company recognized several growth targets at the margins of the current pit and at the edge of the Corner Area reserve.

Higher-grade oxide results from the priority Corner SW target area include,

- Hole 14-SAGRC-196 grading 3.52 grames per tonne (g/t) Gold over 18.3 metres from 32.0 metres downhole

- Hole 14-SAGRC-177 grading 0.34 g/t Gold over 15.24 metres from 27.4 metres downhole

The targets are the extensions of mineralized corridors defined by grade control drilling and through a comprehensive re-logging and multi-element re-assaying program undertaken by Heliostar geologists in H1, 2025. The higher gold price environment has also increased the potential of certain lower-grade areas that were not previously a focus at San Agustin.

Figure 2: Plan map of San Agustin showing oxide gold growth targets with drilling and blasthole data shown.

Sulphide Exploration Targets

San Agustin is a very large mineralized system that hosts a significant volume of gold, silver, lead and zinc mineralization immediately beneath and adjacent to the current pit.

This mineralization is not amenable to conventional heap leaching, and metallurgical work undertaken by the Company has indicated grades are not high enough for economic extraction at present prices.

However, higher-grade results have been returned from within the sulphide domain at San Agustin, including,

- Hole SA-133 grading 0.49 g/t Gold, 25 g/t Silver, 0.2% Lead and 1.0% Zinc over 297 metres from 16.5 metres downhole

- Hole SA-184 grading 0.60 g/t Gold, 15 g/t Silver, 0.1% Lead and 1.0% Zinc over 196 metres from 172 metres downhole

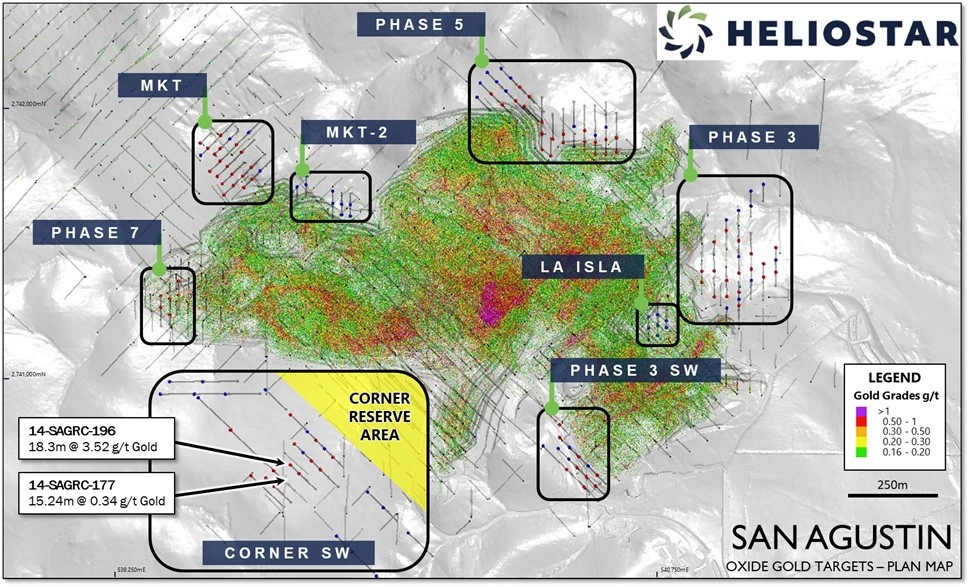

Figure 3: Geochemical and Geophysical footprints at San Agustin with the four sulphide targets labelled.

Similar to central Mexican, gold-rich polymetallic, intrusive-related deposits, including the Pe�asquito and Camino Rojo Mines, also contain higher grade zones of gold and silver mineralization, demonstrating the potential for defining high-grade mineralization within the San Agustin system. Investors are cautioned that mineral deposits on other properties are not indicative of mineral deposits on the Companys properties.

In H1 2025, Heliostar geologists built the most detailed geological model completed to date of the San Agustin deposit. This model proposes that the bulk of the gold and silver mined to date is from an intermediate sulphidation vein system that sits above intrusive related breccias and to the southeast of an interpreted intrusive/breccia centre that is believed to have a porphyry source.

This interpretation generated four significant new porphyry/breccia targets beyond the previously drilled mineralization. These four zones are adjacent to and northwest from the San Agustin pit. These targets are supported by geology, alteration vectors, geophysical signatures and significant geochemical footprints. The Company believes they have strong similarities to those at the Pe�asquito deposit.

Upon completion of the oxide drilling, the Company intends to test these new sulphide targets, looking for high-grade mineralization at San Agustin.

Silver Vein Targets

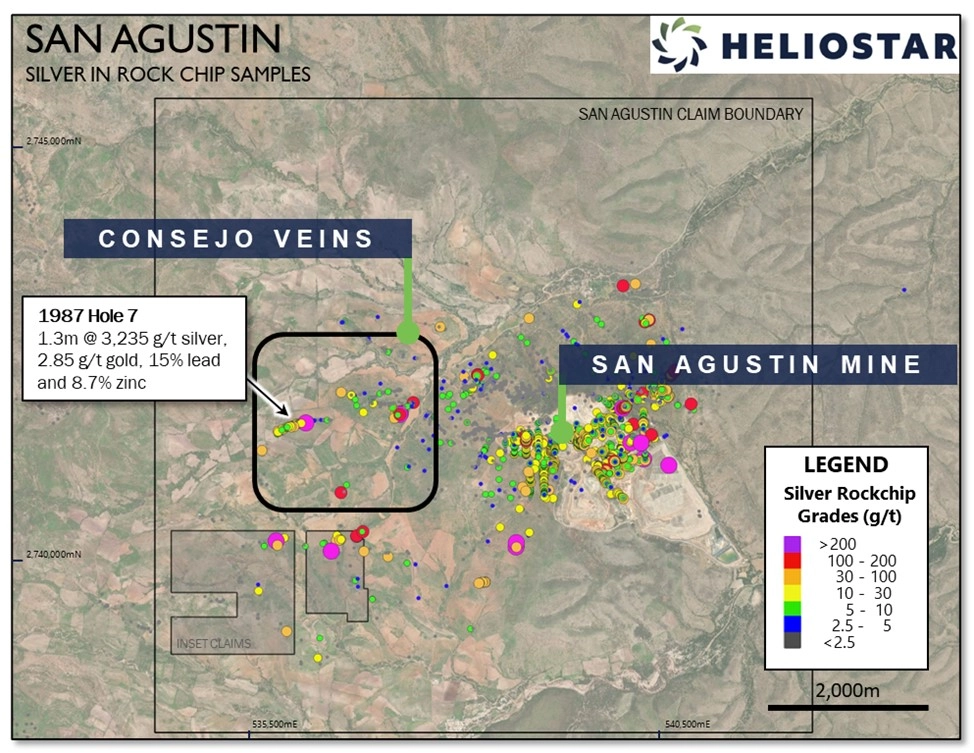

Figure 4: Silver in rockchips at San Agustin with Consejo Vein target and selected drill hole labelled.

In 2021, the previous operator acquired a large claim block from Fresnillo Plc to support an expansion of the open pit. This increased the San Agustin land package to 5,884 hectares. Since this acquisition, no significant regional exploration has been undertaken on these acquired claims.

The regional exploration targets at San Agustin include the Consejo vein prospect. Last drilled in 1987, these veins include intercepts such as 1.3 m grading 3,235 g/t silver, 2.85 g/t gold, 15.0% lead and 8.7% zinc (Consejo de Recursos Minerales, 1985). There has been no drilling on these veins since the initial government program 38 years ago. Heliostar will undertake a modern sampling and target generation program focused on these veins and across the broader claim package to define additional drill targets in H2, 2025.

Note: A qualified person has not been able to independently verify the assay results in the drill intersections presented here, and Heliostar plans on conducting additional work at San Agustin to establish the grades and widths of targets on the property.

San Agustin Reserve Table from Technical Report

Notes to accompany Mineral Reserves table:

- Mineral Reserves are reported at the point of delivery to the process plant, using the 2014 CIM Definition Standards.

- Mineral Reserves have an effective date of 30 November 2024. The Qualified Person for the estimate is Mr. Jeffrey Choquette, PE, of Hard Rock Consulting, LLC.

- A 0.156 g/t AuEq cut-off is used for reporting the Mineral Reserves in oxide, and a 0.310 g/t AuEq cut-off is used for reporting Mineral Reserves in transitional material. Cut-offs were calculated based on a gold price of US$1,900/oz Au, silver price of US$23/oz Ag, processing costs of US$4.23/t for oxide, processing costs of US$5.14/t for transitional, general and administrative costs of US$1.40/t, refining and selling costs of US$0.66/t, gold recovery of 66% for oxide and 38% for transitional and a silver recovery of 10% for oxide and transitional. The AuEq calculation uses the formula AuEq = (Au + Ag/equivalency factor), where equivalency factor = ((Au price in US$/g * Au recovery) / (Ag price in US$/g * Ag recovery)).

- Mineral Reserves are reported within the ultimate reserve pit design. An external dilution factor of 5% and a metal loss of 3% have been factored into the Mineral Reserve estimate.

- Tonnage and grade estimates are in metric units.

- Mineral Reserve tonnage and contained metal have been rounded to reflect the accuracy of the estimate, and numbers may not add due to rounding.

Qualified Persons

Gregg Bush, P.Eng., Mike Gingles, MBA, Stewart Harris, P.Geo, and Sam Anderson, CPG, the Companys Qualified Persons, as such term is defined by National Instrument 43-101 Standards of Disclosure for Mineral Projects, have reviewed the scientific and technical information that forms the basis for this news release and have approved the disclosure herein.

About Heliostar Metals Ltd.

Heliostar aims to grow to become a mid-tier gold producer. The Company is focused on increasing production and developing new resources at the 100% owned La Colorada and San Agustin mines, and on developing the Ana Paula, Cerro del Gallo and San Antonio deposits in Mexico.

FOR ADDITIONAL INFORMATION PLEASE CONTACT:

Charles Funk President and Chief Executive Officer Heliostar Metals Limited Email: [email protected]

Phone: +1 844-753-0045